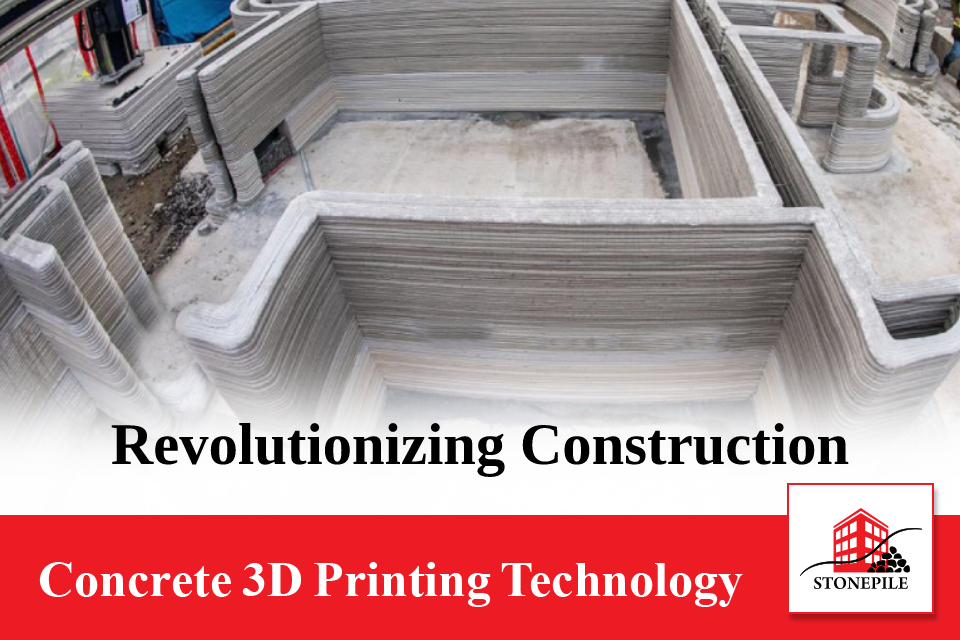

The construction industry is witnessing a monumental shift in an era marked by technological leaps. 3D printing is leading the charge with its groundbreaking technology. This transformative fusion of practical construction knowledge and cutting-edge printing techniques reshapes the prefab and modular construction landscape, presenting unparalleled opportunities for construction professionals and general contractors. Let’s embark on a journey through revolutionary Autonomous Robotic Construction System (ARCS) technology and explore the remarkable projects redefining the future of construction.

Case studies-SQ4D’s 3D Printed houses

Transforming traditional construction methods, the progress in 3D printing technology is highlighted by innovative projects. It demonstrates the potential of 3D printing to create complex, customizable structures at a fraction of the time and cost.

Riverhead, New York

In the heart of Riverhead, New York is the first 3D-printed home listed for sale in the United States. This home includes 3 bedrooms and 2 full bathrooms and features an open floor plan. Approximately 1,400 square feet of living space, plus a 750 square foot 2 ½ car garage on a ¼ acre, is a testament to innovation. The home was printed on-site using revolutionary Max ARCS, a feat that earned it the distinction of being the first 3D-printed home slated to receive a certificate of occupancy. This groundbreaking property was listed for sale as new construction for an enticing $299,999.

Calverton, New York

The world’s largest permitted 3D-printed home was completed in Calverton, New York, in January 2020. This 3-bedroom, 1-bath home spanned an impressive 1,900 sqft and was constructed in just forty-eight hours of print over eight days. The cost-effectiveness of this endeavor was further underscored by the fact that the entire construction utilized less than $6,000 in materials. The project’s success paved the way for future enhancements to the ARCS system, promising even more efficient print times in subsequent projects.

Islandia, New York

This project is a 2,000-sq-ft 3D-printed home in Islandia, New York, featuring 4 bedrooms, 2 bathrooms, a garage, and 9-foot ceilings. This particular project not only highlighted the size but also the proportion of the home that utilized 3D printing technology. Construction of this home took just 15 print days to complete. Unlike many other 3D-printed homes, the project went beyond walls, encompassing the literal foundation, including the slab, footings, foundation walls, interior walls, and exterior walls.

The ARCS Printer

The core of these remarkable projects is the cutting-edge technology known as Autonomous Robotic Construction System (ARCS. Unveiled in 2018, the ARCS printer is a gantry-style construction 3D printer designed for many applications, including homes, roads, bridges, and commercial buildings. This specialized printer has been engineered to outperform traditional construction methods by reducing time and cost by up to 70%.

The ARCS printer’s design incorporates 2 columns and one truss following a track on the ground, allowing it to move left and right. Additionally, the columns and truss facilitate movement up and down as well as back and forward. This unique mobility provides the printer with the flexibility needed to construct a wide range of structures with precision and efficiency.

Structure and Construction Methodology

One of the distinguishing features is the use of concrete throughout the construction process. Unlike conventional wood-framed construction, these 3D-printed homes deliver unparalleled strength and durability. The ARCS printer is not limited to walls; it takes responsibility for the entire foundation, including the slab, footings, foundation walls, interior walls, and exterior walls.

The construction process involves stacking layers of extruded concrete on top of each other, with the printed walls serving as formwork. The specific components of its mortar mixture are undisclosed, but it has Portland cement, aggregate (in the form of sand), and water. The cavity present within the wall is able to be filled with structural columns (which can be inferred to be rebar and concrete), utilities, and insulation. In addition to placing material inside the cavity, metal staples (while they are still wet) are also placed into the concrete layers connect the inside and outside layers better.

Benefits of 3D Printing Technology

As the construction industry embraces 3D printing technology, a multitude of benefits emerge across various dimensions. Let’s delve into these advantages under four key headings:

Cost Effectiveness

- Reduced Labor: These 3D-printed homes require as few as three people, resulting in a significant reduction of labor costs by up to 41%.

- Affordable Materials: The cost of materials for a 3D-printed home from start to finish is less than $6,000.

- Building Cost Reduction: The concrete construction reduces overall building costs by 30%.

Faster Construction Speed

- Streamlined Processes: Eliminating over 20 manual, labor-intensive processes like siding, framing, and sheathing achieves faster build times.

- Record-Breaking Construction: The completion of a 1,900-square-foot home in just 48 hours of print time showcases the unparalleled speed of 3D printing technology.

Design Flexibility

- Architectural Innovation: 3D printing technology allows for the creation of complex, customizable structures that go beyond the limitations of traditional construction.

- Breaking Size Records: 3D printing technology continually breaks size records, showcasing the flexibility of design possibilities.

Sustainability

- Mold and Fire Resistance: 3D-printed structures inherently resist mold and fire, enhancing their longevity and safety.

- Severe Weather Resilience: These structures are built to withstand severe weather conditions, contributing to long-term sustainability.

Challenges and Future Prospects

While 3D printing technology brings about a host of benefits, it is not without its challenges. Regulatory approvals, material optimization, and broader industry adoption are areas that require ongoing attention and refinement.

Conclusion: A Future Defined by 3D Printing in Construction

3D printing technology signifies more than just construction innovation; it represents a transformative shift in how we approach building homes and structures. ARCS technology is shaping a future where construction is faster, more cost-effective, and environmentally sustainable. It’s evident that 3D printing is not just a construction method; it’s a revolutionary leap toward a more efficient and sustainable future.

As the construction industry embraces sustainable building practices, education programs are swiftly incorporating modules on 3D printing technologies. This proactive approach is equipping the next generation with the skills needed for innovative construction careers. In the world of Construction education and careers, professionals are diving into online courses to enhance their skills. These courses cover a range of topics like 3D printing, modular construction, HVAC, plumbing, electrical systems, architecture, and structural components. The goal is to provide a comprehensive training experience for individuals in the Construction community, fostering their professional development. This learning journey not only connects subject matter experts but also creates a network within the Construction industry, allowing access to valuable insights and the latest news-Stonepile Community. As technology like 3D printing transforms the field, these online courses empower professionals to shape the future of construction.

Furthermore, these evolving educational platforms facilitate networking opportunities in construction, enabling aspiring professionals to connect with industry leaders. This connection is invaluable for gaining insights into the industry and staying abreast of the latest construction advancements, particularly those related to large-scale 3D printing.

Source:

1. 3D Printed Houses Changing The Way The World Is Built™ | SQ4D

2. etda.libraries.psu.edu/files/final_submissions/27830

Stay connected on our social media.