In an era where rapid healthcare responses and adaptability are more critical than ever, the rise of modular hospitals marks a turning point in medical infrastructure. For construction professionals, modular experts, and engineers, this new wave of construction promises not only challenges but also immense opportunities for innovation. But what exactly are modular hospitals, and why have they become a solution of choice in recent times?

From transforming existing locations to implementing cutting-edge technology, this blog post explores the world of modular hospitals and the myriad solutions they offer for building resilient healthcare systems.

What Are Modular Hospitals?

Modular hospitals are healthcare facilities constructed using prefabricated modules. These modules are built off-site under controlled factory conditions and then transported to the final location for assembly. This method of construction is gaining popularity due to its many benefits, including reduced construction times, lower costs, improved quality control, and significant flexibility in designs.

Modular construction in healthcare goes beyond mere structure creation; it extends into the installation of mechanical, electrical, and plumbing (MEP) systems, which can also be prefabricated as module racks or bathroom pods to enhance efficiency further. These innovations usher in a new era of hospital construction that is responsive to immediate demands and future-ready.

Why are hospitals turning to Prefabrication?

The adoption of prefab methodology in hospital construction is not a coincidence but a response to several compelling drivers:

- Accelerated Construction: Modular construction enables hospitals to become operational much quicker than traditional methods allow. This rapid pace is especially crucial in emergency situations or regions with a dire need for medical facilities.

- Cost Efficiency: With most of the work being done off-site, modular building reduces the overall cost by limiting the amount of on-site labor and minimizing construction waste.

- Sustainability: Prefabricated modules can be designed with sustainable materials and methods, reducing the environmental footprint of the construction process.

- Quality Control: Building components in a controlled environment reduces the risks associated with on-site construction, leading to better quality and safety standards.

- Flexibility: Modular hospitals can be easily expanded, reduced, or repurposed as healthcare needs change, making them a smart long-term investment.

Solutions to Building Modular Hospitals

Building a modular hospital involves several innovative solutions to meet the complex needs of healthcare delivery.

Transforming Pre-existing Locations

By utilizing the modular approach, existing structures can be quickly transformed into fully functioning medical facilities. This adaptability is invaluable, particularly when addressing sudden healthcare crises.

Accelerating Construction with Technology

Modern technologies like Building Information Modeling (BIM) allow for meticulous planning and coordination of every aspect of the hospital’s design before construction begins, ensuring precision and reducing the chance of errors during assembly.

Highly Configurable Spaces

The prefabricated nature means that modular hospitals can provide highly configurable spaces that cater to different medical services with minimal adjustments to the layout, offering unprecedented flexibility to healthcare providers.

Effective Disease Control

Modular designs facilitate controlled environments that can be optimized for disease control, which is paramount in a healthcare setting.

Wireless Access Control

Advanced access control systems can be integrated to provide security and controlled area access that is vital for hospital operations.

Case Study: MECART PREFAB MODULAR HOSPITAL

In response to the urgent need for healthcare facilities during the COVID-19 pandemic, a groundbreaking project emerged, challenging the norms of traditional construction. Mecart and its collaborators achieved the seemingly impossible task of constructing a modular hospital in less than 9 months, a feat that would typically take 8 to 10 years.

Project Overview:

- Location: Montreal, Canada

- Industry: Healthcare

- Application: Oncology

- Dimensions: 34,000 sq. ft., 36 prefab patient rooms

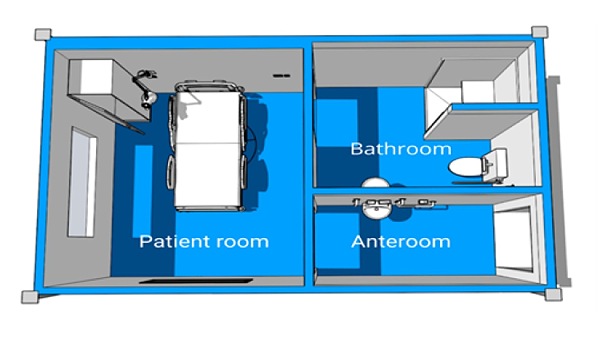

The modular hospital featured 36 prefab individual patient rooms spread over two floors, with a particular focus on creating isolation rooms for an immuno-oncology center catering to cancer patients. Each patient room was thoughtfully equipped with a private shower, toilet, and television, ensuring the comfort of individuals undergoing prolonged treatment.

Innovative Design and Construction:

One of the notable aspects of this project was the integration of fully prewired hospital patient rooms. The electrical, mechanical, plumbing, and ventilation services were seamlessly incorporated during the manufacturing process, transforming the rooms into “plug-and-play” units ready for immediate connection on-site.

For the first time in hospital construction, a fully pre-assembled patient room, complete with an anteroom and ensuite washrooms, was introduced. This innovative approach not only optimized space but also enhanced efficiency in the utilization of modular solutions, a departure from the conventional use limited to washrooms due to size constraints.

Airborne Infectious Isolation rooms (AII rooms)

-

- Prefabricated In tandem with on-site construction, reducing lead time by half. Learn more here Airborne Infectious Isolation (AII) rooms with negative-pressure differential | MECART – YouTube

Advanced Hospital Room Design:

- Equipped with a bay window for easy cleaning and improved patient visibility.

- Touch-free handwash stations for enhanced hygiene.

- Individual ADA-compliant washrooms for accessibility.

Versatile Configurations:

- Offering unlimited options for customization to meet diverse needs.

Factory Prefabrication for Quick Delivery:

- Entirely factory-built for efficient ground delivery, ensuring timely completion.

- Fast and easy commissioning, minimizing downtime and delays.

Integrated Systems:

- Electrical, mechanical, and plumbing systems are seamlessly integrated into each unit.

- HVAC system for autonomous operation with individual controls

Air Quality Management:

- Contaminated air extraction system for enhanced safety.

- Fresh, filtered air supply with HEPA filtration, prioritizing occupant well-being.

Easy Maintenance and Reusability:

- Surfaces are designed for easy cleaning and are resistant to common chemicals.

- Reusable post-pandemic, ensuring long-term value.

- Long-Term Construction: Built for permanent use, ensuring durability and longevity.

Adaptable Spaces:

- Convertible into protected environment rooms with positive differential pressure, adding flexibility to the design.

Key Achievements

Reduced Lead Time: Collaboration between Mecart and construction teams allowed the simultaneous progress of concrete pouring for the foundation and room construction in the factory. This synchronized effort resulted in a 40% reduction in lead time compared to standard construction projects, showcasing the efficiency of modular construction.

Ultramodern Features: The patient rooms themselves were designed with modernity and functionality in mind. Exterior bay windows, touchless automatic handwashing stations, and a complex monitoring system for air quality demonstrated a commitment to patient well-being and safety. These ultramodern features were critical in ensuring the mental health of long-term patients and optimizing healthcare delivery.

Adaptable to Health Emergencies: Originally built to cater to immunosuppressed patients undergoing cancer treatment, the modular hospital quickly adapted to the urgent need for additional healthcare infrastructure during the pandemic. The 34,000-square-foot facility, equipped with 36 dual-pressure respiratory isolation rooms, enabling the adjustment of air pressure to either positive or negative levels based on the specific requirements of the treated patients, showcased versatility by serving patients with COVID-19 and other infectious diseases.

Environmental Impact: Modular construction not only ensured rapid delivery but also required fewer on-site workers, minimizing the risk of workforce shortages and reducing the spread of COVID-19.

Collaborative Success and Community Impact:

The achievement of building a modular hospital in record time was made possible through the collaborative efforts of various stakeholders. Architectural firms specializing in HVAC, plumbing, and electrical systems joined forces with both traditional and modular construction teams and collaborated, bringing distinct expertise to ensure the success of the project. This modular hospital stands as a tangible result of applied knowledge in modular construction gained through subject matter expert courses, which played a crucial role and a testament to the collaborative spirit of local companies addressing community needs. Check out the courses here.

Construction professionals specializing in architecture, structure, and other relevant courses came together; they not only built a healthcare facility but also formed valuable connections within the construction networking community.

Conclusion

This case study highlights the transformative power of modular construction in healthcare, offering speed, efficiency, and adaptability to unforeseen challenges. The success of this project not only broke records driven by a community of construction industry leaders and subject matter experts but also set a new standard for healthcare facility construction. This emphasizes the potential of modular solutions, supported by continuous construction training and professional development, in addressing urgent healthcare demands. Stay updated on such industry news and insights by connecting with the vibrant construction community and accessing relevant courses to enhance your construction career.

Source:

1. Prefab Hospital: How We Built a Modular Hospital in Under 9 Months (mecart-cleanrooms.com)

Stay connected on our social media.