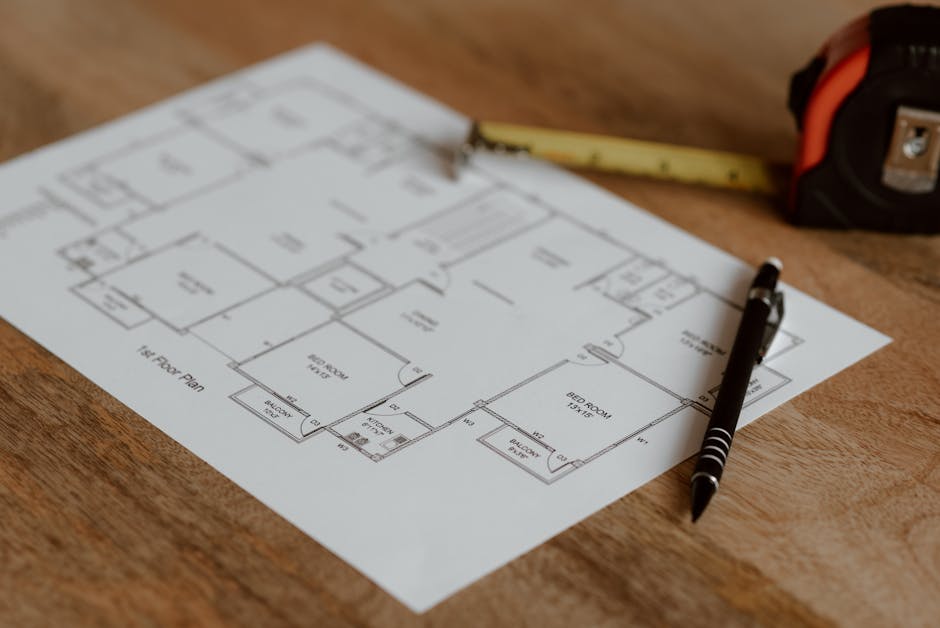

Importance of building layout design in construction

Good building layout design plays a crucial role in reducing steel structure costs. Here’s why:

- Efficient Space Utilization: A well-thought-out layout ensures optimal use of space, minimizing the amount of steel needed for construction.

- Minimizing Wastage: A good design can help reduce material wastage, saving money on unnecessary steel purchases.

- Improved Structural Stability: An effective layout design can enhance the building’s stability, reducing the need for excessive steel reinforcements.

- Streamlined Construction Process: A carefully planned layout can expedite the construction process, ultimately cutting down on labor costs and time.

By prioritizing the layout design in construction projects, you can significantly impact the overall steel structure costs.

Factors that influence steel structure costs

The cost of a steel structure can be affected by various factors. Here are some key points to consider:

- The size and complexity of the building design can impact the overall cost.

- The type and quality of materials used in the construction process play a significant role in determining the final expenses.

- The location of the construction site can influence transportation costs for materials and labor.

- Labor costs, including wages and availability of skilled workers, can also affect the total expenditure.

How optimizing building layout design can save on steel costs

Optimizing the design of your building layout can help you save on steel costs significantly. When you plan the layout efficiently, you can utilize the steel structure in the most effective way, minimizing wastage. This means you can achieve the desired strength and stability using less steel, which directly lowers your overall construction expenses. By strategically placing load-bearing walls and columns, as well as optimizing the spacing between them, you can reduce the amount of steel needed for your project. A well-thought-out design can also streamline the construction process, leading to additional savings in labor costs.

Key principles of cost-effective building layout design

To make your building layout cost-effective, consider these key principles:

- Space Efficiency: Optimize space utilization to reduce the amount of steel needed.

- Material Selection: Choose economical materials without compromising quality.

- Modular Design: Implement modular elements to streamline construction and reduce labor costs.

- Optimal Structural Planning: Conduct thorough structural analysis to minimize steel usage.

- Natural Lighting and Ventilation: Include design elements to reduce energy costs and enhance comfort.

- Flexibility in Design: Plan for future modifications to avoid costly renovations later on.

The relationship between building layout and material efficiency

When planning the layout of a building, the design directly impacts how effectively materials are utilized. A well-thought-out building layout can lead to significant savings on steel structure costs. Here’s how the arrangement of spaces and structures within a building can affect the efficiency of materials:

- Optimized Space Utilization: Efficient building layouts can ensure that materials are used effectively, reducing waste and minimizing the amount of steel needed for construction.

- Minimized Material Wastage: By planning the building layout strategically, it is possible to minimize the cutting of materials and reduce leftovers, thus cutting down on unnecessary material wastage.

- Streamlined Construction Process: A thoughtfully designed layout can contribute to a smoother construction process, preventing the need for material rework and additional resources, ultimately saving on steel structure costs in the long run.

Strategies for reducing steel structure costs through layout design

When designing the layout of a building, consider the placement of structural components like columns and beams to minimize the amount of steel needed. Optimizing the layout can reduce the overall steel structure costs significantly. By carefully planning the arrangement of the building’s elements, you can maximize the efficiency of the steel materials used, leading to cost savings without compromising the structural integrity of the building.

Case studies on successful cost reduction through layout design

Case studies show that strategic building layout design can significantly reduce steel structure costs. For example, by optimizing the placement of support beams and columns, construction companies have cut expenses during the building process. Additionally, incorporating efficient material flow paths within the layout has resulted in savings on labor and construction time. Implementing smart design strategies can lead to substantial cost reductions in steel structure projects.

Collaborative design approaches for lowering steel structure expenses

Collaborative design approaches involve teamwork between architects, engineers, and construction professionals to optimize the building layout and reduce steel structure costs. By working together, these experts can find innovative solutions that maximize efficiency and minimize the amount of steel needed for the structure. This approach can lead to significant cost savings while ensuring that the building’s integrity and safety are maintained. By incorporating collaborative design approaches, project teams can achieve a balance between aesthetics and functionality, resulting in a cost-effective steel structure that meets the project requirements.

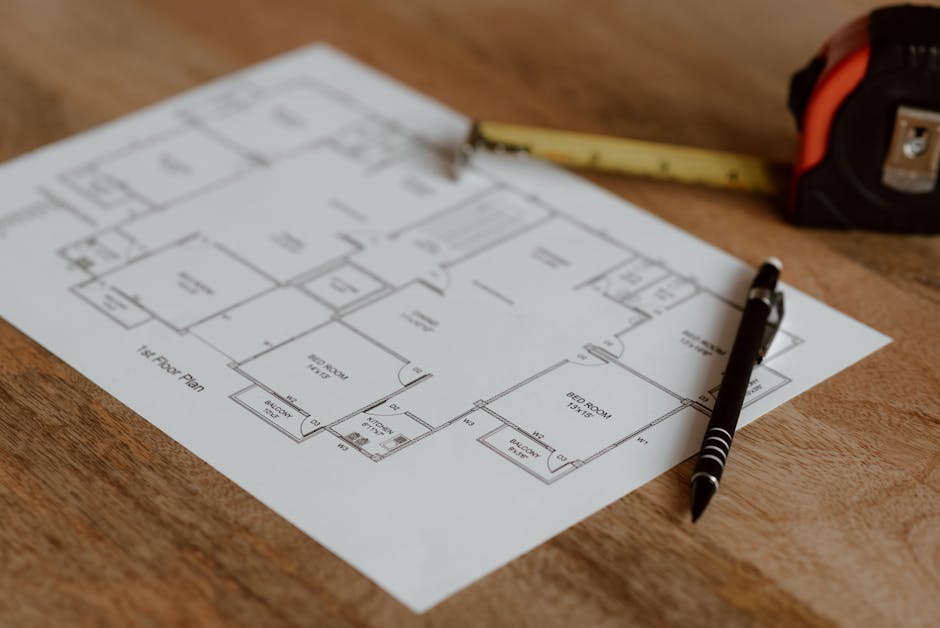

Utilizing technology for efficient building layout design

Using technology can help optimize building layout designs, leading to more efficient use of steel and reducing construction costs. By employing computer-aided design (CAD) software, architects and engineers can create detailed and accurate building layouts. These tools allow for precise measurements, better visualization of the final structure, and easy modifications. Additionally, building information modeling (BIM) technology enables stakeholders to collaborate in real-time, enhancing the overall design process and reducing errors. Optimizing building layout design through technology can significantly impact the cost-effectiveness of steel structures.

Conclusion: Achieving cost savings through strategic building layout design

To reduce steel structure costs, strategic building layout design is crucial. By optimizing the layout, you can minimize material waste and streamline the construction process. This leads to significant cost savings in the long run. Utilizing efficient space planning and considering factors like material flow and accessibility can result in a more cost-effective steel structure project. Through careful planning and design, you can achieve your desired cost savings without compromising on the structural integrity of the building.