MEP racks are modular structural frames that incorporate standardized MEP components. These components include the rack structure itself, cable trays, electrical components, HVAC ductwork, piping, insulation, and sometimes framing and drywall for specific installations.

Why are Hospitals using MEP racks?

In response to the shortage of skilled labor in the construction industry, including those with specialized skills obtained through construction education, Metropolitan Mechanical (MMC) and other MEP contractors are strategically implementing MEP racks for HVAC projects within hospitals. This innovative approach involves prefabricating key components off-site, effectively reducing the dependency on on-site labor, a significant consideration for professionals seeking construction career advancement.

The adoption of MEP racks in hospital construction addresses several critical aspects, offering a multitude of advantages for those pursuing subject matter expertise in the field. As construction professionals seek construction community connections and engage in online construction courses, the integration of MEP racks aligns with the industry’s move towards modular construction.

The strategic implementation of MEP racks in hospital construction not only streamlines the process but also brings about a significant reduction in on-site labor dependency. This innovative approach is central to the ongoing evolution of construction methodologies, where efficiency and precision are paramount. For an in-depth look at how prefabrication and the use of sub-assemblies are making waves across various construction projects, not just healthcare, explore this insightful article Elevators Installed and Ready in 1 Week – BASE4

Significance of Emergency Services:

Hospitals, as vital institutions providing emergency services, require flawless designs and constructions, particularly in the planning of MEP (Mechanical, Electrical, Plumbing) systems. The consistent layout across the entire facility, facilitated by prefabricated MEP modules, ensures streamlined maintenance and efficient service functioning, crucial for emergency medical services and the professionals undergoing HVAC, plumbing, and electrical courses.

Advantages of Prefabricated MEP Modules:

Prefabricated MEP modules bring several benefits to hospital construction, offering a comprehensive solution for various applications, including corridors, bathroom pods, risers, and walls. The modules, with lengths ranging from 6 to 12 meters, integrate cable trays, pipes, steel frames, and ventilation ducts, ensuring a seamless and efficient construction process. This approach aligns with the goals of those seeking architecture and structure courses online, emphasizing efficiency in design and construction.

Off-Site Fabrication Process:

The off-site fabrication process involves constructing MEP modules in specialized workshops, a practical application for those undergoing construction training. Builders utilize tools such as tower cranes, duct lifters, and chain blocks for transportation and fitting at the construction site. This approach enhances efficiency and precision in the construction of MEP systems within hospitals, providing valuable insights for industry leaders and professionals seeking professional development.

Efficiency Enhancement with ‘Plug & Play’ Technology:

The integration of ‘plug & play’ technology in ceiling/riser corridor prefab modules contributes significantly to efficiency. Pre-installation of ductwork, cables, and pipework streamlines the installation process, offering a time-saving and cost-effective solution for hospital construction projects. This technological advancement is relevant for professionals participating in online construction courses and staying updated on industry insights and construction news.

Prime Candidacy of Hospitals for Mechanical Racks:

Hospitals emerge as prime candidates for the implementation of mechanical racks due to their diverse service requirements. Mechanical racks facilitate the installation of essential services, including VAV boxes, heating and cooling lines, electrical lines, communication lines, domestic water lines (hot and cold), fire protection mains, airlines, and specialty waters, providing valuable networking opportunities within the construction industry.

Role of Fire Wall Integration:

The incorporation of a firewall into the mechanical racking system plays a crucial role in expediting hospital construction. This integration ensures compliance with safety regulations while enhancing the overall efficiency of the construction process. It also contributes to the knowledge base of construction industry leaders, promoting collaborative efforts and sharing industry insights.

Addressing Traditional Delays:

Mechanical racks eliminate traditional delays where wall contractors precede MEP contractors, causing bottlenecks in construction projects. The integration of mechanical racks fosters collaborative and efficient work among all contractors, addressing delays and ensuring a smooth construction process in hospital projects. This collaborative approach aligns with the principles of construction networking, fostering connections among professionals in the construction community.

Considerations While Installing MEP Racks in Modular Hospitals

When venturing into the realm of prefabrication for MEP (Mechanical, Electrical, Plumbing) modules, strategic planning becomes paramount. Here are essential considerations to ensure a seamless pre-fabrication process, combining efficiency and compliance:

Early Collaboration with MEP Specialists & Contractors:

Early engagement with MEP specialists and contractors streamlines service distribution.

Contracts in the initial stages enhance work quality, reducing material waste through the utilization of BIM (Building Information Modeling).

Project/Site Management for Bulky Modules:

Adequate arrangements for lifting equipment and delivery paths must be made early on, given the potentially bulky/heavy nature of MEP modules.

Calculating module weight and transport time in advance contributes to quicker fixation and eliminates inefficiencies in project management.

Maintenance, Renovation & Replacement Considerations:

Strategically planning space and valves around MEP modules is crucial for future maintenance needs.

The inclusion of maintenance requirements in pre-fabrication sketches ensures a proactive approach to upkeep and renovations.

Code & Regulation Compliance Assurance:

Stakeholders must ensure strict adherence to local codes and regulations applicable to each system during prefab MEP module installation.

Utilizing BIM Technology for Integrated Workflows:

Incorporating Building Information Modeling (BIM) technology facilitates integrated workflows during fabrication.

Prefabricated construction BIM proves indispensable in healthcare buildings, with a growing interest in leveraging bathroom pods for substantial cost savings in hospitals.

Case Study: Saint Joseph Hospital

Overview:

Saint Joseph Hospital, located in Denver, stands as a testament to modern construction innovation. Completed in 2015, this eight-story, 831,000-square-foot healthcare facility boasts a comprehensive range of medical care and support spaces. With a price tag of $386 million, it includes a diagnostic treatment wing, a 260-bed tower area, medical office spaces, and a central HVAC plant. The construction utilized a post-tensioned concrete cast-in-place superstructure complemented by prefabricated steel stud infill panels.

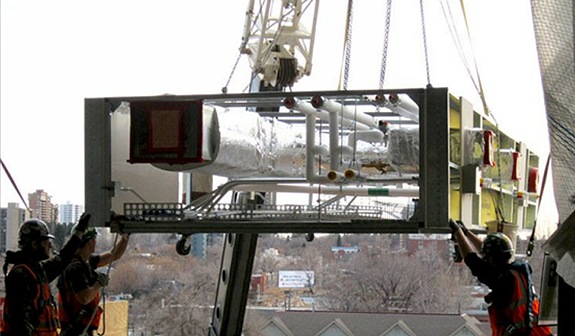

Crane Lifting of MEP Racks

Crane Lifting of MEP Racks

MEP Rack being rigged and hoisted from a truck bed up to the access opening provided

MEP Rack being rigged and hoisted from a truck bed up to the access opening provided

Mortenson’s Innovative Approach:

Leveraging ownership of Blue Vera, a non-combustible wall panel and MEP rack off-site manufacturer based in St. Paul, MN, Mortenson spearheaded the off-site prefabrication process. The project involved the prefabrication of 427 headwalls, 440 bathroom pods, 346 exterior panels, and 250 multi-trade racks, showcasing the effectiveness of Industrialized Construction (IC).

MEP Rack being set onto the egress opening platform

MEP Rack being set onto the egress opening platform

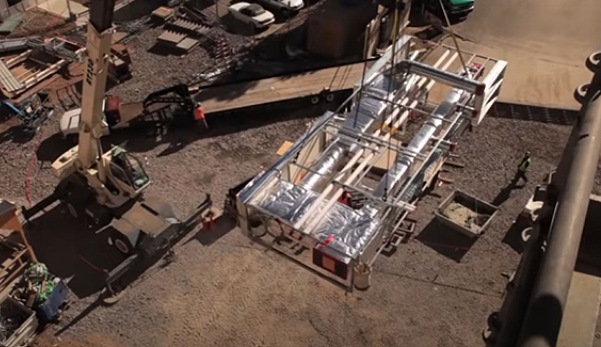

Lifting Equipment to move MEP racks into place and lift to secure

Lifting Equipment to move MEP racks into place and lift to secure

HVAC System Excellence:

The HVAC system, a crucial component of the hospital, featured a two-story central plant housing three 1,000-ton chillers, three 3,000 gpm cooling towers, and heating provided by three 700 HP dual-fuel boilers. The MEP multi-trade racks, measuring 8′ by 25′, integrated plumbing, med gas, sheet metal ductwork, electrical components, pneumatic tubing, and upper corridor walls.

Savings and Benefits:

The implementation of prefab strategies yielded multiple advantages for the end customer. Mortenson’s commitment to cost-effectiveness, time efficiency, and quality resulted in an accelerated 30-month schedule, a year shorter than traditional hospital builds. For every dollar invested in prefab, approximately 13% returned as a quantifiable benefit to the project.

Recognitions and Sustainable Practices:

Built-in adherence to LEED® standards and following the Green Guide for Health Care, Saint Joseph Hospital earned an Economic Impact Award from Brownfield Renewal and an Award of Merit from Engineering News-Record (ENR) magazine. The project exemplified design integration and modeling, with Mortenson’s Internal Revit/BIM Model specialists playing a crucial role in creating comprehensive coordination models for Industrialized Construction scopes of work.

Efficiency and Rework Reduction:

The success of the project can be attributed to extensive pre-planning and on-site co-location, leading to a significant reduction of over 4% in rework compared to similar construction projects. The HVAC subcontractor’s report highlighted the positive impact of Mortenson’s approach on minimizing RFIs and conflicts during construction. Explore online construction courses, including specialized MEP courses, to stay at the forefront of industry advancements and enhance your skills here.

Conclusion:

Saint Joseph Hospital stands as a true success story, implementing various Industrialized Construction (IC) strategies to meet the customers’ needs efficiently. The project showcases the transformative power of prefabrication, contributing to a more cost-effective, time-efficient, and sustainable future for healthcare construction.

Stay connected on our social media.